Scroll compressor

Scroll compressor is one of positive movement compressor where compressing of refrigerant is created by rotation and assist of two inner spirals.

History of scroll compressor

One of the most popular compressors in HVAC and refrigerant applications is scroll compressor. Initial design first established by a French engineer in 1905. The design was far ahead of its time and impossible to be built with existed technology back then. However, from 1907 primary samples was presented. After USA and Japan researches, Scroll compressor has used in HVAC&R applications since 1980.

Scroll compressor today

Scroll compressor presents in various models, Based on different usage in HVAC and refrigeration systems. In general, reliability and efficiency of scroll compressor make them as one of the best option for residential and industrial utilization.

How does scroll compressor work?

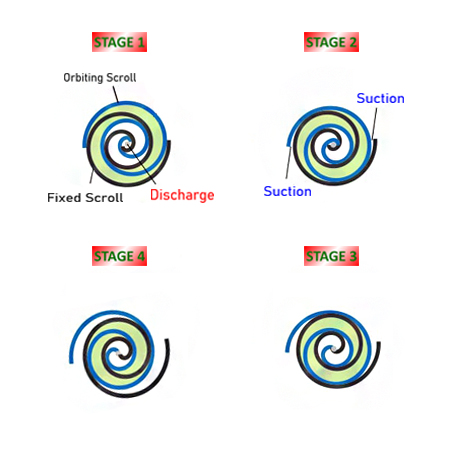

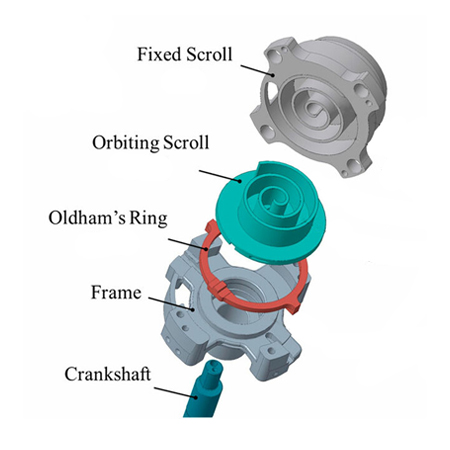

Scroll compressor consists of two spirals, one is fixed-stationary scroll which is attached to its body and the other one is orbiting scroll that rotates through the use of swing link. Refrigerant gas enters the space between two spirals from suction port and with spiral movement rotation, refrigerant are slowly pushed to the center, causing the increasing of gas temperature and pressure while reducing of volume. The superheated gas then exits though the exhaust port to the discharge line.

Scroll compressor structure

Scroll compressor is fully hermetic and normally made of steal and is attached to cylinder. Most of scroll compressors are built vertically and the spirals are installed on top of the motor.

Generally, scroll compressor doesn’t need suction and discharge valves to be installed on pipes. However, in some refrigeration and under zero applications installing discharge valve increases compressor efficiency.

Types of scroll compressor

Based on rotation and type of motor, scroll compressor usually is design in two models:

Fixed speed scroll compressor

Fixed speed or single stage scroll compressor works in only one specific speed which means the amount of passed refrigerant is constant. The fixed speed scroll compressor is the simplest and economical version of scroll compressor.

Variable speed scroll compressor

This type of scroll compressors are equipped with variable speed technology and divided into Digital scroll and Inverter scroll technology. In this types of compressor capacity would be control in small steps and constantly changing the compressor efficiency in a broad range.

Advantages of scroll compressor

- Compact design & low weight

- Simple structure

- Quiet operation

- High efficiency in part load and full loud mode

- Low vibration

- Less maintenance required

Disadvantages of scroll compressor

- Fully hermetic design

- Lower ESEER rather than Screw one in high capacity applications