Brazed plate evaporator

Brazed Plate heat exchanger or BPHE

Since 1980, when brazed plate heat exchangers entered the market, until today, various applications have been defined for it. Refrigeration industry has been one of the main industries uses this type heat exchangers due to the many advantages of them such as closed structure, high working pressure, high efficiency and compact dimensions. brazed plate evaporator is one of the main applications of this type of heat exchangers in this industry. In addition, BPHE can be used as a condenser, economizer, de-superheater, oil cooler, sub-cooler and intermediate heat exchanger in various types of cooling processes.

Brazed Plate evaporator structure

Like other evaporator heat exchangers there are to fluids in the heat exchanger, Refrigerant fluid on one side and water or brine fluid on the other side. The plates material in these evaporators are usually stainless steel and the brazing material between the plates is usually copper. A distributor is installed on the refrigerant and evaporator inlet side (liquid line) for uniform distribution, increasing efficiency and preventing freezing.

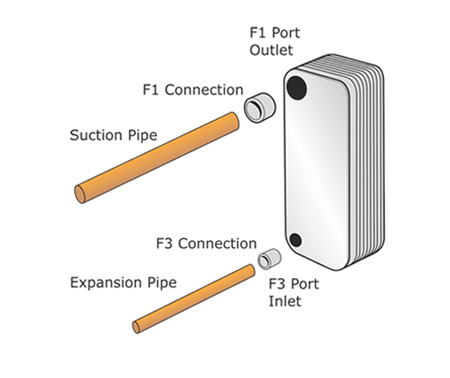

Brazed plate evaporator connections

Normally, the plate evaporator has four main connections, two connections for the inlet and outlet of the refrigerant and two connections for the brine fluid, and two sub connections are also available to install the thermostat and antifreeze accessories. The type of connections on the refrigerant side are Solder and on the other side is usually threaded or Rotalock that depended on the flow rate and capacity of the process fluid. Usually, due to the high density of the liquid refrigerant, the inlet refrigerant connection is at the bottom and its outlet (refrigerant vapor) is installed at the top of the plate evaporator. For easier installation, the brine fluid connections are usually placed on the opposite side, however, according to the customer's order, all connections can be installed on same side.

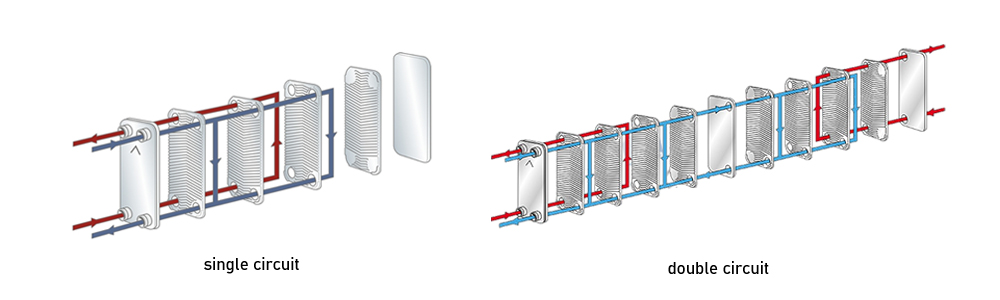

Types of circuits in Brazed plate evaporator

When evaporator capacity is increased, it is common to divide the total cooling load between two independent refrigerant circuits. In this way, the system safety and flexibility will be increased compared with using only one refrigerant circuit. Otherwise, most refrigerant systems are designed to supply a nominal cooling load higher than the normal cooling demand. The system consequently operates most of the time at part load with one or more compressors inactive.

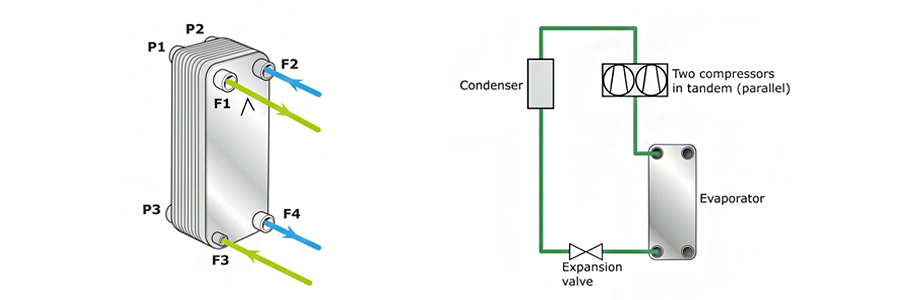

Single circuit brazed plate evaporator

The single-circuit brazed plate evaporator has a refrigerant circuit and a brine circuit. Refrigerant as a mixture of liquid and gas enters the evaporator from the lower connections, F3 or P3, and leaves from the upper connections, F1 or P1.

If the brazed plate evaporator is a counter flow type, the brine fluid enters from P2 or F2 and exits from F4 or P4. If that is co-current flow, the direction of entering and leaving the brine fluid will be opposite. In order to ensuring stable evaporation and cause the refrigerant would be surrounded by brine, the side of the brine fluid in the plate evaporator will always have one more channel.

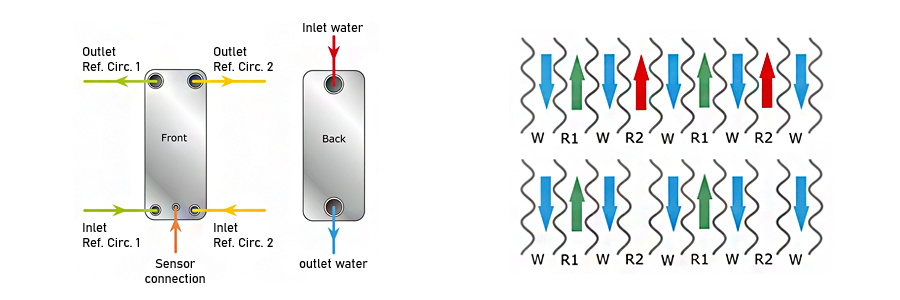

Dual circuits brazed plate evaporator

The dual-circuits brazed plate evaporator has two independent refrigerant circuits and a brine fluid circuit. The two-circuit plate evaporator is cross-flow type, and like the single-circuit, the R1, R2 refrigerant is surrounded by the brine fluid W.

Advantages of brazed plate evaporator

Some advantages of this type of evaporator can be mentioned as follows:

- High efficiency

- Light weight

- Compact design

- Low refrigerant needed

- No need to PUMP-DOWN

- Easy to installation

There are no products to list in this category.