Reciprocating compressor

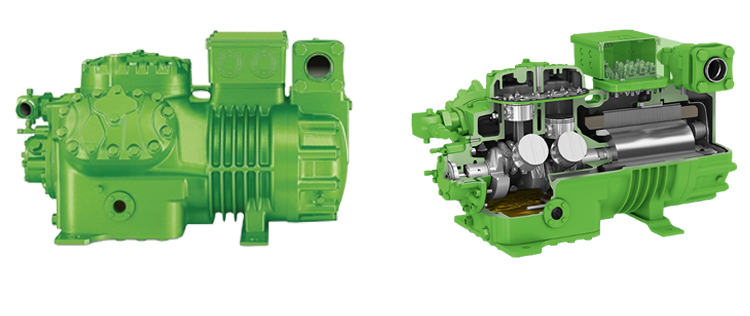

One type of compressors that is very common in air conditioning and refrigeration systems is the reciprocating or piston compressor. This type of compressor is used in different capacities. Today, the reciprocating compressor has given its place to the rotary compressor and the scroll compressor, especially in lower capacities and air conditioning applications. but in industrial process and especially sub-zero applications piston compressors the first choice.

How a reciprocating compressor works

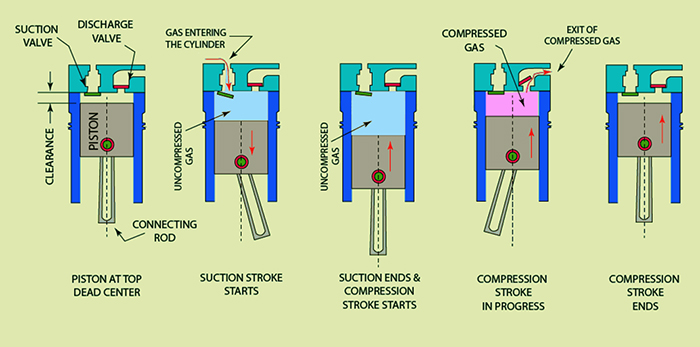

The structure of the reciprocating compressor is very similar to the internal combustion engine. This compressor has one or more cylinders and pistons, along with special valves for entering and exiting refrigerant, crankshaft, connecting rod and other small parts. One end of the crankshaft is connected to the electric motor and the other end is connected to the piston through the connecting rod. Due to the movement of the electric motor, the crankshaft moves and causes the piston to move linearly inside the cylinder. The vapor of refrigerant enters the cylinder through the suction valve, is compressed by the piston, and its pressure and temperature increase, and then it leaves the compressor and moves towards the condenser through the discharge valve.

Reciprocating compressor advantages

It can be mentioned simple and repairable mechanism, operation at low temperature and different capacities as some advantages of piston compressor.

Reciprocating compressor disadvantages

Due to the large number of moving parts in piston compressor, the level of noise and vibration is generally high and periodic services and maintenances is more than other types. In addition, the piston compressor has a low efficiency and is very vulnerable to liquid refrigerant return. Therefore, the amount of superheat should be considered high in this type of compressor, which causes increasing temperature of motors and power consumption.

There are no products to list in this category.